All about the community of model railroading and rail enthusiasm

June 2024

By TIM BLACKWELL/Cowcatcher Magazine

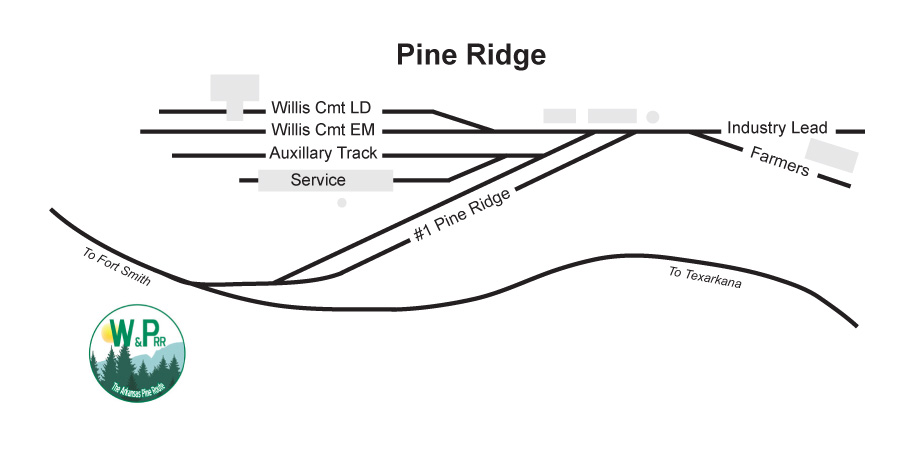

Some areas on a layout are cantankerous, maybe dreaded, by operators and even the superintendent. Early on, Pine Ridge had all the telltale signs of being the one spot on the Whitehurst & Pine Ridge Railroad that just wouldn’t work.

The small town is one of three on a branch line operated by the W&PRR on the Cowcatcher’s protolance N-scale layout.

The W&PRR runs on a section of the former Missouri Pacific line to Ozark, AR, where a canning plant was served. Today, the main attraction there is Greystone Cement, which unloads bulk material for truck distribution. On the other side of town is Farmers Union, a small grain and seed business. Near the main line sits the W&PRR’s only diesel shop, a single-stall brick structure dating to the steam era.

Each operating session, the W&PRR local handles about 20 or more loaded and unloaded 37-foot hoppers at the cement plant and maybe spots a car or two at Farmers Union.

Greystone receives up to a dozen loaded hoppers that are cycled into the unloading shed on three tracks. Each holds six or seven cars.

Simple enough? Meh.

The problem is that Pine Ridge sits on a small piece of real estate with one track at Willis Yard adjacent to the spur into town. The track was built to hold about six of the 2-bay hoppers and it can get awfully tight when the Van Buren local arrives with loads.

Also, the W&PRR’s switcher can only feed five or six cars at a time into Greystone because of limited capacity on the industry lead beyond the yard switch. The snug configuration usually means making multiple moves to get loads into the plant.

Inbound trains, of course, bring in as many cars as can fit, causing angst for the Pine Ridge operator. Add an extra car or two for Farmers Union, and things get stickier.

The area has received a lot of thought since three years ago, when branch line operations began. And it has taken three attempts at an operating scheme (and one infrastructure improvement) to get it right.

Access to Pine Ridge is off of Union Pacific’s main line from Texarkana to Fort Smith. The W&PRR has trackage rights with UP, its parent company, to get back and forth between Pine Ridge and its classification yard in Van Buren.

The original operating scheme called for southbound and northbound UP trains to ferry loaded cement cars to the W&PRR interchange in Fort Smith. There the W&PRR’s Van Buren local picked up inbound cars and set out outbound empties for the next UP train.

Loaded or inbound cars were assembled in Van Buren into W&PRR Train No. 2, powered by a pair of GP30s, which pulled them southbound to Pine Ridge. Because of the compact track layout, it took coordination from Train No. 1, the Pine Ridge local, and Train No. 2 to switch Pine Ridge, especially if the train had more than six cars.

In a perfect scenario, inbound cars from Van Buren were spotted on the yard track, and the Geeps ran around on the spur or lead track toward the UP main. The engines waited until Train No. 1 brought the unloaded cars to haul back to Van Buren, then on to Fort Smith.

If Train No. 2 had more than six inbound loads (usually the case), it got dicey.

Cars were spotted on the yard track and spur. The diesels went to the engine house to wait while Train No. 1 cleared both tracks and brought out empties for the yard track. If Train No. 1 had more than six empties, Train No. 2 might have to pull down toward the UP main line switch to get ahead of cars. Or Train No. 1 could set three or four cars on the service track behind the engines and the rest on the yard track. The Geeps would back out of the service track and run ahead of the cut on the yard track, then tie on.

A lot of jockeying around. To ease the problem, W&PRR management invested in lengthening the yard track by 75 feet which shortened the distance between the yard switch and main line switch on the spur. Capacity was expanded to eight cars (nine in a pinch), with just enough room left between the yard and main line switches to hold Train No. 2’s GP30s.

While it was a big investment, the plan was better. But Train No. 1 still had to work around Train No. 2’s power while managing loads and empties.

The issue intensified when demand for cement went through the roof. Greystone needs more cars to meet orders.

The W&PRR and UP teamed to have certain Dallas-to-Kansas City (northbound) manifest trains deliver up to a dozen cars direct to Pine Ridge rather than leaving them at the Fort Smith interchange. Loaded cars are backed into town onto the yard track and empties are picked up.

Larger cuts of cars may be left up to the main line switch or on the lead once empties are picked up. Conceivably, Pine Ridge can accommodate up to 17 cars; Train No. 1 picks them up and shoves them into waiting tracks at the cement plant.

With the new agreement, cement hoppers no longer have to route through Van Buren and be shuttled by Train No. 2. Now, the W&PRR’s Pine Ridge switcher can work without interference from another train to pick up and set out cars from Greystone.

Train No. 2 still runs to Pine Ridge but just to serve Farmers Union and fill smaller car orders for Greystone.

Space on the industry lead remains limited and may require drilling multiple cuts into the plant, but the calculated, tight moves on the yard track and spur into town are no longer in play. The engineer breathes a little easier.

Now Pine Ridge is one of the most enjoyable switch jobs on the railroad.

This is an updated version of the story that appeared in the May/June 2023 Cowcatcher.