All about the community of model railroading and rail enthusiasm

By TIM BLACKWELL/Cowcatcher Magazine

Over the summer, industry buzz began intensifying about Walthers’ new Layout Control System, the under-table-mounted switching approach that’s virtually plug and play. After installing a slow-motion Vertical Switch Machine on one of the nine turnouts on the Cowcatcher’s Northwest Tarrant & Pacific, we understand why.

The system is a step above similar under-table-mount products that require soldering and running wires for HO, N, Z, S and O scales.

Walthers sent the Cowcatcher a complete starter system,which includes the switch machine, distribution block, two-amp/12-volt filtered DC power supply, drill set and a dual bi-color LED fascia turnout controller.We did not receive equipment to adapt stall motor switch machines, like the popular Tortoise turnout system, which was due in late 2018.

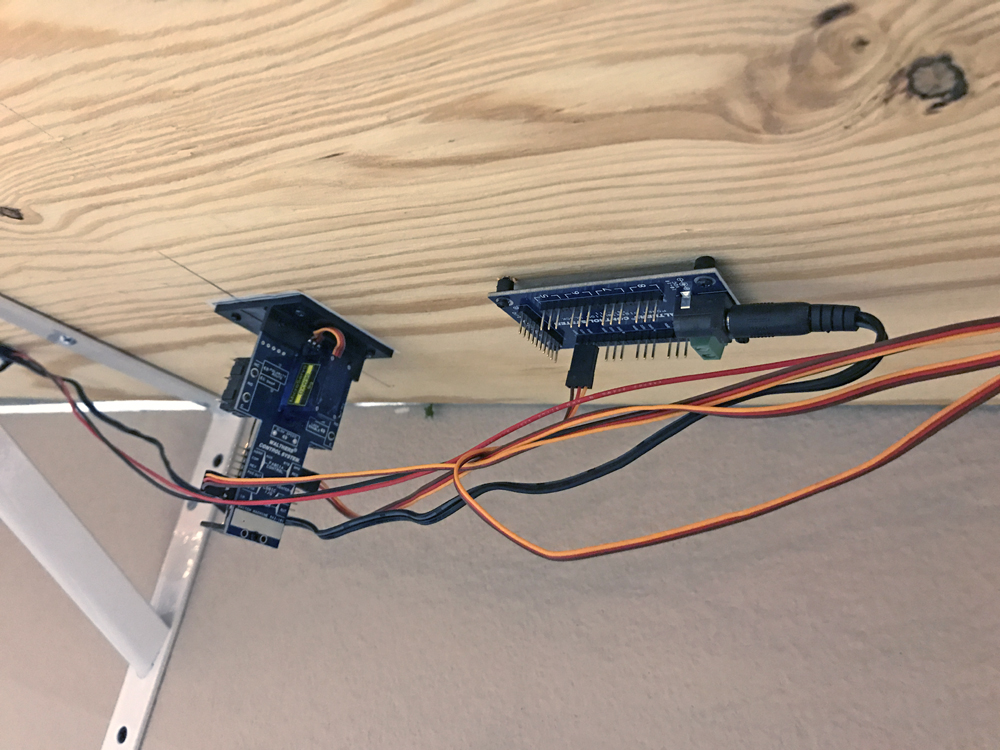

The factory-assembled, servo-based unit is easy to install,using plug-in cables to and from the machine and distribution block to an independent power source. The system can be powered from a power pack by plugging the DC power supply into a wall outlet.

A big advantage is that hook-up doesn’t require soldering, which is common with other remote switch machines,and stringing stranded wire. No more lying on your back or contorting under the layout with a hot soldering iron welding wires.

We chose the siding for the concrete plant off the spur leading to American Warehouse on the NT&P for installation. The machine is sleek at 3 3/8 inches tall and fit nicely under the layout. A horizontal machine that requires less height to is available for multi-deck layouts.

An output rod or throw bar is centered on the turnout and controls one-second switch movement from left to right. Adjustable throw and tension ranges from 1/32 of an inch to a half-inch (1 mm to 12 mm) for turnouts to accommodate scales from Z to O.

Installation involves drilling holes for the output rod using a cookie-cutter template provided by Walthers, then mounting the switch machine, distribution block and fascia turnout controller. Once each was installed (small screws are provided), it’s just a matter of plugging in the cables to the appropriate outlets.

Simple.

However, do watch the installation videos at https://www.walthers.com/products/walthers-control-system. They helped speed installation.

The only question was removing the center jumper on the switch machine board. The jumper holds the switch machine in the center position − it comes that way from the factory to ensure proper location under the layout − when power is applied. The jumper covers two input prongs used in DCC mode and must be removed for DC operation. In DCC mode, the machine also can be operated from a throttle, thus eliminating the fascia turnout controller.

Neither instructions nor videos fully explain that the jumper is what covers the input prongs. At one point we thought the prongs needed to be removed.

Fortunately, we looked online a tthe Switch Machine Reference Guide, as suggested in the instructions, and realized we only needed to slide off the jumper.

After installation and powering up the system, everything worked perfectly. No adjustment was needed on the throw bar from the machine, although thorough instructions to adjust rod travel were included.

The turnout controller takes a firm push to activate, which prevents accidentally throwing the switch by bumping into the fascia.

A key to installation is working with the right tools, and Walthers thankfully makes available the correct drill bits, including a brass step bit that matches the diameter of controller pushbuttons and LED indicator bezels for panel mounting. The step bit is also good for wallowing out the hole for the throw bar under the turnout for proper turnout travel.

The starter system is ideal for powering pre-installed turnouts but existing turnouts can be converted by removing the switches to drill the hole for the throw bar.

Cost of materials to install one switch and the system, according to Walthers’ website, is about $89. Or use your own bits and save $12.

In all, the Walthers Switch Machine system is a nice addition to the layout without the muss and fuss of older technology. Turnouts are thrown realistically, and installation and wiring are neat and compact.

The system has plenty of add-on capacity with the distribution block, which reduces the overall cost per switch.